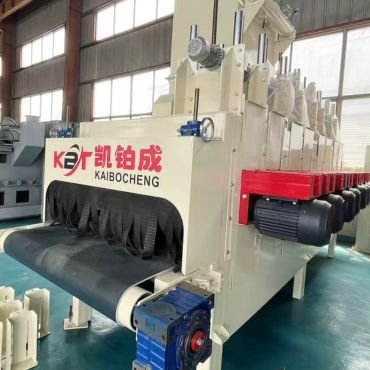

Brushed Stone Machine Model: KBC-1300-8S

Brushed Stone Machine for Brushed Finishing Aged Surface Stone Pavers

- Making brushed finishing or aged surface

- Its suitable for marble granite limestone stone and concrete products

- No need water

- No dust

- High capacity

- It has changed the traditional way of stone surface treatment

What is Brushed Stone Machine

Brushed stone machine is used for surface treatment of stone, mainly for cleaning, polishing and grinding stone to make its surface smoother and more beautiful. It is usually equipped with rotating brush heads, which removes dirt, aging layers or uneven parts on the surface of the stone through high-speed rotation and friction. It can process water brush surfaces, leather surfaces, aged surface.Its suitable for natural stone materials such as marble and granite, as well as concrete products.

This dry method brushed finishing processing technology does not require water or drying equipment at all, effectively protecting the environment, reducing processing costs, and greatly improving its speed. It is the latest and better choice for stone manufacturers and concrete product factories.

Brushed Stone Machine By Working Width

Brushed stone machine’s working width has 900mm,1200mm,or we can customized for customer’s speacial needs.

1050-8S Brushed stone machine process brushed surface finishing with max width 900mm,its used for washed stone surface or after shot blasting to make the surface more silky or leather like.

1300-8S Brushed stone machine is working with max width 1200mm,its suitable for marble,granite,stone,limestone,concrete products,pavers,terrazzo.

Brushed Stone Machine By Brushes

Our brushes are customized, different from all types on the market, with long usage time and low processing costs.

Brushed Stone Machine By Power

Brushed Stone Machine Feature Box

ISO 9001

PLC Program

Good Brand

Pollution-free

Leading Brushed Stone Machine Manufacturer

Jiangsu Kaibocheng Machinery Co., Ltd. is a leading industry enterprise specializing in the production of brushed stone machines, focusing on the research and manufacturing of efficient surface treatment equipment in the fields of stone and concrete brick processing. The company has changed the traditional way of water brushing with innovative technology as its core. The brush has the characteristics of long service life, strong wear resistance, and uniform treatment effect. It is widely used in the processing of brushed surface effects on marble, granite, concrete products, and other materials.

Brushed Stone Machine Without Water

Traditional stone brushing requires a large amount of water resources and generates sewage and dust pollution. However, the waterless brushing stone machine developed by Jiangsu Kaibocheng Machinery adopts dry processing technology, which can complete the brushing process of stone without water source, completely solving the water treatment problem of customer factories, reducing environmental pressure, and saving water resources and sewage treatment costs. Provide customers with efficient, energy-saving, and environmentally friendly modern stone surface treatment solutions.

Multi-functional Brushed Stone Machine

High adaptability brushed stone machine is suitable for various types of stone such as marble, granite, quartz, limestone,concrete pavers,terrazzo tiles etc., with uniform and delicate processing effects.Widely used, Kaibocheng helps enterprises upgrade.

Jiangsu Kaibocheng Machinery Co.,Ltd.-Leading the way in waterless stone brushing technology

As an industry benchmark, Jiangsu Kaibocheng Machinery Co., Ltd. has created a new benchmark for environmental protection and efficiency and advanced production technology and strict quality management system,the waterless brushed stone machine we developed has updated the processing method of the brushed finishing surface,. Its products are exported to both domestic and foreign markets, providing customized solutions and comprehensive after-sales service to customers, helping stone and concrete products processing enterprises improve efficiency and quality.

Brushed Stone Machine Inspection and Delivery

Kaibocheng machinery usually conducts raw material testing, process testing, and finished product testing, and records the results of each test in detail for easy traceability and analysis. Regularly generate inspection reports, analyze the quality of processing procedures and equipment status, and propose improvement suggestions. Ensure the quality of the machine.

Jiangsu Kaibocheng Machinery Co., Ltd. adopts waterproof film protection packaging to ensure the safety of equipment transportation. After being loaded into the container, it is reinforced for convenient transportation and safe delivery, ensuring that customers receive goods more worry free.

Latest Brushed Stone Machine Projects

After a paver block factory in China used our waterless brushed finishing stone machine, the efficiency increased by more than 5 times, the environmental protection standards were met, and the products were exported. Zero dust pollution and awarded the title of “Green Factory”.

After using our waterless brushed stone machine, the stone building materials factory achieved zero wastewater discharge and was awarded the provincial-level “Clean Production Demonstration Enterprise”.

- Gallery

- Data Sheet

- Details

| Brush | 8Pcs |

| Power: | 59.1kw |

| Voltage: | 380/customized |

| Max width | 1000mm |

| Speed | 0-5m/min |

| PLC | With PLC program |

| Dust collector | Pulse type |

| Brush height | Adjustable |

Jiangsu Kaibocheng Machinery provides superior quality assurance and serves global customers.

Our company has an independent research and development team to develop a new generation of brush finishing stone machines. The machines have passed international certifications such as ISO and are sold both domestically and internationally. We provide customized solutions and lifelong technical support to ensure worry free use for our customers.

Choosing Kaibocheng waterless brush finishing stone machine means choosing an efficient, environmentally friendly, and sustainable future for stone processing!

Related Product

Why we choose dry method brushed stone machine?

The core advantages of using dry method brush finishing surface:

Environmentally friendly and pollution-free: No need for water, completely avoiding wastewater discharge and sludge treatment issues, meeting strict environmental requirements;

Cost reduction and efficiency improvement: Save on water circulation system costs and water consumption expenses, simplify maintenance, and reduce overall costs by over 30%;

Stable quality: Intelligent dust removal technology ensures dust-free processing, uniform and delicate surface treatment, and improved product yield;

Wide applicability: It can operate stably in water scarce areas and low-temperature environments in winter, breaking through the limitations of traditional water brush surface areas.

Dry process technology is a key solution for upgrading stone processing to green and intelligent manufacturing

1-2 workers.

Yes,we have oversea installation and aftersale service.

Yes,we spply the spare parts.

1 Year

35 days