Brushing Finishing Machine for Granite and Stone: KBC1050-8S

The main benefits of dry brushing finishing stone (shot blasting or brushing directly without adding water) are as follows:

- Enhanced slip resistance

- Highlight natural texture

- Reduce the risk of water stains

- Environmental protection and water saving

- Enhance durability

- Saving Producing cost

What is Brushing Finishing Machine for Granite and Stone?

Jiangsu Kaibocheng brushing finishing machine is a process of mechanically brushing and grinding the surface of stone under dry and waterless conditions, mainly used to enhance the antique, matte or anti slip effect of stone. The brush machine is used to rotate and polish at high speed to form a uniform antique texture.

Dry brush finishing stone advantage:

1.Preserve the natural texture of the stone and prevent water stains and pollution.

2.Enhance slip resistance, suitable for outdoor areas, stairs, and other areas.

3.Environmentally friendly and energy-saving, no need for large amounts of water.

Suitable for scenarios such as antique bricks, cultural stones, outdoor flooring, etc.

Brushing Finishing Machine for Granite and Stone By Model

Jiangsu Kaibocheng Machinery has 1050-8S and 1300-8S dry brushing finishing machine.

1050-8S Brushing finish machine’s max working width is 900mm, the motor of brush is 5.5kw.Its suitbale for akk kinds of stone and concrete product surface dry brush finishing.

1300-8S Brushing finish machine’s max working width is 1200mm, the motor of brush is 7.5kw,suitable for marble granite stone and cocnrete pavers and slabs.

Brushing Finishing Machine for Granite and Stone By Motor

Jiangsu Kaibocheng machinery customize the machine with different motor power to meet various requirements.

Brushing Finishing Machine for Granite and Stone By Another Feature Like Stone Type

Our brushing finishing machine has a large widelt usage:marble,granite,limestone,quartz,concrete pavers,slabs.

Brushing Finishing Machine for Granite Feature Box

ISO Certificate

PLC Control

Pollution-free

Brand Electronic

Dry Brushing Finishing Machine for Granite and Stone

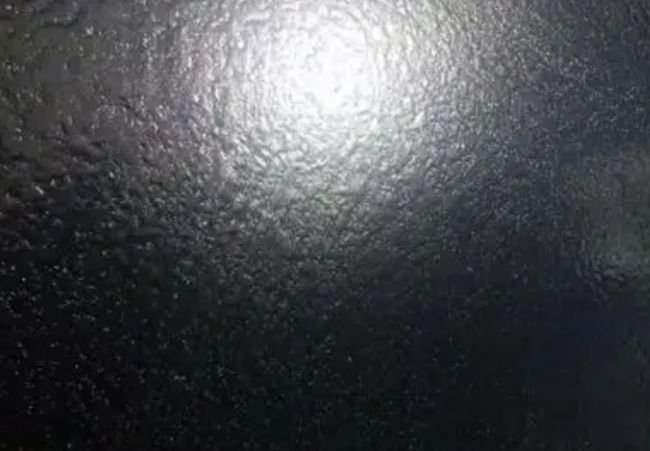

The traditional leather antique surface craftsmanship uses water brushing. Kaibocheng Machinery has developed a new processing method that does not require adding water. This eliminates the water treatment and pollution problems that stone factories are troubled by, and saves time and cost. Dry polishing and soft brushing remove the soft components on the surface, forming a matte antique texture. The surface presents a natural abrasion texture, with a soft touch and anti slip and wear-resistant properties.

Professional Brushing Finishing Machine for Granite and Stone Manufacturer

Jiangsu Kaibocheng Machinery Co., Ltd. is a professional manufacturer of stone brush machines, specializing in the research and manufacturing of surface treatment equipment for granite, marble, and other materials. The company provides customers with efficient processing solutions for antique brush surfaces, leather surfaces, anti slip surfaces, etc. with advanced technology, stable performance, and fine craftsmanship. Winning market trust with high-quality products and meticulous after-sales service, and assisting the innovative development of the stone industry.

Multi-functional Brushing Finishing Machine for Granite and Stone

The dry brushing finishing machine process leather antique finichsing surface,by professional brushing machines and can be widely used for surface processing of materials such as granite, marble, concrete bricks, and artificial stone slabs. Realize efficient processing of “one machine, multiple materials”

Jiangsu Kaibocheng Machinery Co.,Ltd.

Jiangsu Kaibocheng Machinery Co., Ltd. focuses on the research and manufacturing of stone surface treatment equipment, specializing in fully automatic CNC stone brushing machines, antique surface processing equipment, and multifunctional brushing and grinding production lines. With innovative technology as the core and multiple patents, we provide customized solutions for shot blasting,antique, leather, and anti slip surfaces of granite/marble/concrete. With a professional R&D team and a comprehensive service system, we assist customers in achieving efficient and intelligent production, and continue to lead the industry in technological upgrades.

Brushing Finishing Machine for Granite and Stone Insepction and Delivery

Kaibocheng Machinery adopts process and finished product testing to ensure that each equipment passes the test before leaving the factory, covering core indicators such as motor stability, brush head wear resistance, and dust removal efficiency. All precision errors comply with national industry standards, and exclusive factory testing reports are generated to achieve 100% pass rate delivery, providing customers with long-lasting and reliable equipment guarantee.

Jiangsu Kaibocheng Machinery Co., Ltd. specializes in efficient delivery and ensures safe and timely delivery of equipment. We wrap it with PE film, fix it inside the container, prevent moisture, and track the entire logistics process. Each device comes with a factory inspection report, operation manual, and overseas installation guidance service, allowing you to receive goods without worry and quickly start production!

Latest Brushing Finishing Machine for Granite and Stone Project

Chinese stone factories use our dry brush machines to efficiently process granite antique surfaces, increasing production capacity by 50% and achieving a finished product rate of over 98%, resulting in high customer satisfaction

Brushing finishing machine is used for concrete bricks, with a shiny surface, stronger anti fouling ability, and improved texture.

- Gallery

- Data Sheet

- Details

| Brush | 8Pcs |

| Power: | 59.1kw |

| Voltage: | 380/customized |

| Max width | 1000mm |

| Speed | 0-5m/min |

| PLC | With PLC program |

| Dust collector | Pulse type |

| Brush height | Adjustable |

Jiangsu Kaibocheng Machinery Co., Ltd. subverts traditional stone processing methods with innovative technology, independently develops efficient and energy-saving dry brushing equipment, integrates intelligent control systems with environmental protection processes, and significantly reduces energy consumption and dust pollution. By processing high value-added materials such as antique and anti slip surfaces, we help customers improve their stone processing speed. With a dual drive model of “technology+service”, we continuously create long-term competitive advantages and excess profits for our customers.

Related Product

Why you choose Kaibocheng dry brushing finishing machine for granite marble stone and concrete products?

1. Patent technology, efficient and energy-saving

Adopting independently developed variable frequency speed regulation system and high-quality brushes, it has higher efficiency than traditional equipment.

2. One machine with multiple functions and strong adaptability

The same device can handle various materials such as granite, marble, concrete bricks, quartz panels, etc.

2. Environmental compliance and green production

Integrated pulse dust removal, dust collection rate ≥ 99%, compliant with ISO9001 quality certification system, helping customers pass environmental impact assessments.

3. Intelligent control, stable quality

Equipped with PLC touch screen, real-time monitoring of brush pressure, speed and other parameters, the surface uniformity of the finished product reaches over 98%, eliminating manual errors.

4. Full cycle service, reducing costs and increasing efficiency

Provide overseas installation and debugging services, as well as lifelong technical support, to help customers shorten production cycles and reduce maintenance costs.

You can feeding it by hand, or by automatic stacker,or clamp.

1 Year.

yes,we make voltage according to speial needs.

Yes,we not only making machine,but also make spare parts.

Yes,we have.