Curling Machine: KBC1300-8S

Using brushes to brush paver blocks,slabs,bricks surface softly,make it looks smooth and feel silky when touch the surface:

- Adopts dry way to brush paver’s surface,no need water to treatment,saving cost and space,no pollution,factory is clean.

- Saving producing cost,the dust can be recycle used as raw material mixture.

- Brush height can adjust to curling different thickness paver blocks.

- Automatic control,easy to operation.

- Long life time lasting.

- Oversea installation service.

- Supply spare parts.

What is Curling Machine?

Curling machine uses a high-speed rotating roller brush to curling the surface of paver blocks,slabs,bricks, causing the cement slurry on the surface layer of colored bricks to be brushed off through the roller brush, revealing the color of the colored sand itself, making its surface smooth, slightly glossy, anti slip, better anti fouling, moisture-proof, and less prone to moss growth.

The curling machine is particularly suitable for products with textured surfaces, and can also be used after polishing and shot blasting, improving the texture and grade of concrete products and increasing profit margins.

Generally curling machine equipped with 4 sets (8) of brushes, one set consists of two brushes, arranged in an inclined manner from coarse to fine, with one rotating forward and the other reversing. This design avoids brush marks on the surface of the product.

The conveyor belt speed of the brush machine is variable frequency and adjustable, and the brush is wear-resistant and durable. It is suitable for imitation stone and antique bricks, dry process bricks, and wet process bricks. Welcome to send an inquiry.

Curling Machine By Products

KBC factory’s curling machine can brush concrete products:paver blocks,slabs,bricks,and nature stone:marble,granite.

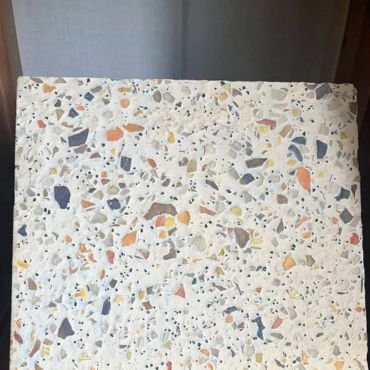

Concrete slabs surface is not shine,and easy to have a layer of dust,after brush by curling machine,concrte slab surface become a matt shine,and very smoothly,and moisture proof and anti slip.

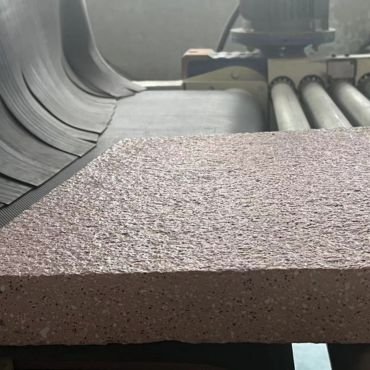

Concrete paver blocks after shot blasting treatment,the surface is rough,then using curling machine to brush the paver block surface,the surface becomes silky and shiny, not easy to breed moss,improvice its quality.

The demand of brick paver blocks surface treatment is increasing,after shot blasting,brush curling,coating,the bricks anti slip, anti fouling, and anti stain penetration are essential surface treatment equipment for brick production processes.

The cement on the concrete brick’s surface was brushed off with curling machine, revealing the aggregates and making the surface feel smooth. This resulted in the brick or paver blcoks being suitable for indoor and outdoor use.

Curling Machine By Model

KBC machine has KBC1050-8S curling machine,KBC1300-8S curling machine,customized curling machine.

Product Feature Box

No sewage

Shippment fast

Saving producing cost

Dust powder recycle use

Curling Machine with PLC Control

Kaibocheng machine manufactrer concrete paver block,slab curling machine with high cost performance,but the quality is very high,it has PLC control and screen to control it,very easy to operate,and understand its operate program,PLC brand can OEM,Through PLC and HMI screen,the workers can easily start the machine,supervise machine operation steps.

Curling Machine Brush-Durable and Easy to Change

KBC Machine curling brush is specially customized, wear-resistant, durable, and will not bend during use. The brush threads are arranged in coarse and fine, from coarse to fine, to give the product a glossy feel. The brush is easy to replace, and can be customized according to customer requirements. It has fast rotation speed, smooth operation, and smooth adjustment of the brush up and down.Brushes 1, 3, 5 ,7rotate in the opposite direction to brushes 2, 4, 6,8.The surface effect of the concrete product is very obvious, without scratches.

High Efficient Dust Removal Structure

KBC1300-8S adopts a dual dust removal system and an exclusively designed pulse type dust removal structure, with high dust removal efficiency. The entire soft brushing process is dust-free, and the working environment is clean. The collected dust can also be recycled as raw materials, reducing production costs. At the same time, pulse dust removal can greatly reduce the energy consumption and cost of the system, which has also played a significant role in the company’s energy conservation, emission reduction, cost reduction, and efficiency improvement

How Can We Reduce Your Worries and Increase Your Confidence in Choosing KBC Machine?

KBC Machine is a professional factory with research and development capabilities that specializes in the concrete products surface secondary treatment machines. We have various research and development patents, constantly updating technology, optimizing machines, and upgrading machines.

We not only produce individual machines, but also manufacturer entire surface treatment machine lines, including palletizers(automatic cube stackers), shot blasting machine, curling machine, coating machines, layer pushing machine, laminating machine, wrapping machine and packaging machines. We approach our customers from their perspective, helping them get machines with high cost-effectiveness and increasing competitiveness. Contact us to learn about us KBC machines

Strictly Quality Control And Attentive Service Are The Firm Choices Of Over 1500 Customers.

KBC machine’s professional technical team first inspect visual inspection of mechanical equipment, followed by functional performance inspection, comprehensively testing the various functions of the mechanical equipment to ensure stable and reliable performance. At the same time, they also need to inspect the power transmission system, electrical system, and other parts of the mechanical equipment to ensure its normal operation.

KBC machine has its own overseas installation and debugging team, carefully installing every shot blasting machine, patiently teaching every customer how to use the machine, daily equipment maintenance, usage precautions, and common problem-solving methods. Our goal has always been to help customers make satisfactory products and proficiently operate our machines.Ensuring customer satisfaction is the core of after-sales service.

Latest project

This customer is an old customer of KBC machine. Five years ago, they purchased our shot blasting machine, which specializes in producing outdoor PC bricks. Now, the customer has higher requirements for the product and needs to perform soft brushing on the bricks. The curling machine is being installed in his factory.

The 1300-8S curling machine can curling layer by layer stacked bricks and blocks, with a width of up to 1200mm. Many brick factories choose this model, which has a wide range of applications and can process a variety of bricks.

The automatic shot blasting machine and curling machine includes an automatic cube stacker, shot blasting machine, and curling machine. The automatic cube stacker reduces manual labor and improves speed. The customer in the picture is using a German brick block machine, but they chose our concrete product surface refinement treatment machine line because our machines have a good processing effect and the price is also very cheap.

- Gallery

- Data Sheet

- Details

| Technical parameter | ||

| Model | KBC1050-8S | KBC1300-8S |

| Working width | 1000mm | 1200mm |

| Product thickness | Adjustable | Adjustable |

| Production speed | 0-5M | 0-5M |

| Power | 57.7kw | 79.16kw |

| Size | 5400*1880*3363mm | 6400*2050*3760mm |

The entire process of curling machine is dry and does not require water, which saves processing costs. It can be used for antique blocks with textured surfaces, paver blocks and slabs after shot blasting. The brush brushes away the cement on the surface, exposing the aggregates, making the surface shiny and improving the quality of concrete products.

After being brushed by curling machine, the water seepage rate on the surface of the brick decreases, which will prevent moisture and prevent slipping. The height of the brush can be adjusted manually or automatically, and the replacement of the brush is also very convenient. Overall, the cost is relatively low.

The operation program of the machine can be operated through the HMI touch screen, which is very simple. Welcome to contact us and exchange more details about brick producing with each other,and for more machine details.

Related Product

Why you need to use a curling machine?

1.Curling machine no need to use water,production environment is very clean.

2.The bricks paver blocks after shot blasting have a natural stone feel, which is very beautiful, but they feel rough when touch it, which requires a curling machine to brush them silky. This is the demand and inevitable law of the development of the brick and paver block industry.

3.The water seepage rate of curled or brushed bricks is reduced, and the moisture resistance, slip resistance, and stain resistance are enhanced, which is a necessary step to improve the quality of bricks.

Why you need KBC curling machine?

KBC curling machine price is cheap with high quality,saving your cost.

Yes,KBC machine is a professional concrete products surface refinement treatment machine manufacturer in China.Our machines have been used in customer factories for a long time and have gained recognition from customers. The technology of the machines is already very mature, and our advantage is we only dothe research and development and production of these equipment, professionalism, and uniqueness.

Yes,KBC machine has oversea aftersell installation team,and we have oversea aftersell service.

Yes,we support OEM for example :Making the curling machine according to customer’s requirements of electronic brand,motor brand.

Yes,wee supply spare parts including the brushes.

30-60days for delivery.