KBC1050-3S Shot Blasting Machine For Concrete Paver Blocks

| Size: | ≈5000×1800×4800㎜ |

|---|---|

| Power: | 7.5kw |

| Voltage: | 380V Customized |

| Hertz: | 50Hz/60Hz |

| Capacity: | 0-5m/min |

| Total power | 40.7kw |

| Working width | 900mm |

| Configuration: | Automatic or Semi-automatic |

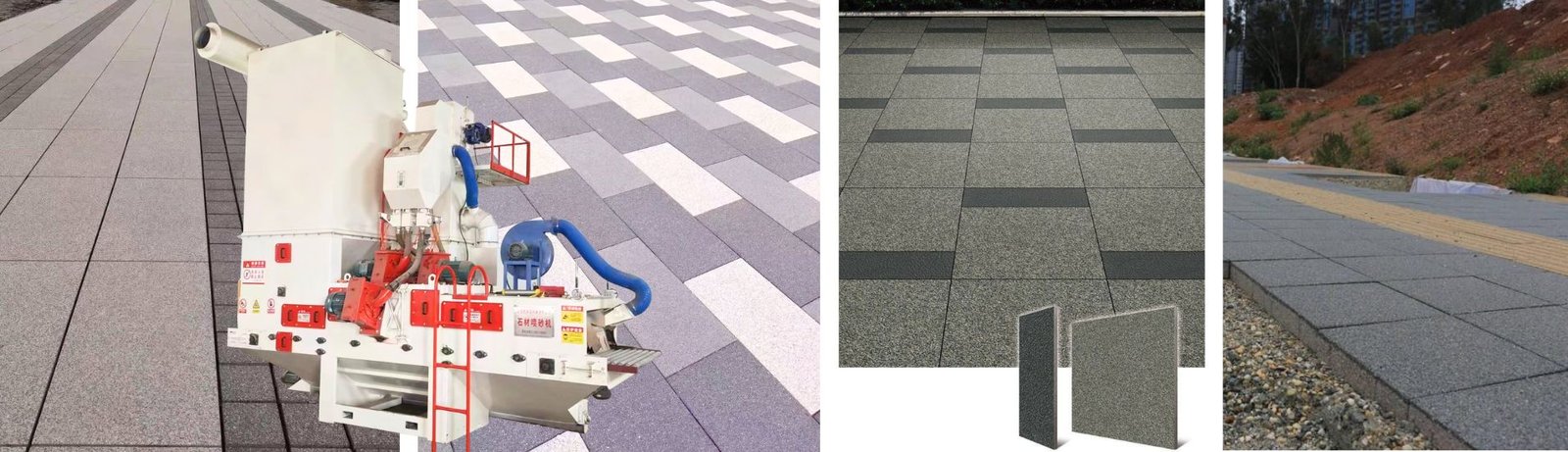

KBC1050-3S Shot Blasting Machine Functions

By using centrifugal force, the shot blasting machine rapidly ejects steel shots to strike the surface, clean, strengthen, deburr or roughen the surface, and create a bush hammer wear effect on paving slabs, bricks, concrete blocks,step bloks,curbstones, granite, marble, and stone surfaces, achieving an antique or vintage style.

Increasing the friction coefficient, avoiding wet sliding, improving aesthetics and safety, is an indispensable processing method in the field of imitation stone pavers.

KBC1050-3S Shot Blasting Machine For Concrete Paver Blocks Applications

Paver blocks bricks shot blasting can efficiently clean the surface, enhance slip resistance, and improve durability.

Kerbstone shot blasting can eliminate processing defects, enhance overall texture, and achieve low-cost high-end landscape effects.

Wet pressing or bricks slabs made from plastic molds can be shot blasted with our shot blasting machine.

The cement surface of the bricks made by the vibrating brick machine is very ordinary. After shot blasting, the quality of the bricks is improved.

The traditional chiseling method has low efficiency, high cost, granite shot blasting speed is high, low cost, and is more environmentally friendly.

Marble shot blasting efficiency increased by 5 times, saving processing costs.

- Our Specialty

- Our Mission

- Our Patents

Jiangsu Kaibocheng Machinery Co., Ltd. is a high-tech enterprise specializing in the research and manufacturing of surface treatment equipment. Its core products include shot blasting machines, sandblasting machines, brushing machines,curling machine, spraying coating machines, dust removal equipment, automatic packaging equipment, etc. Unlike other shot blasting machine manufacturers, Kaibocheng specializes in the stone and concrete brick blocks industries.

We are guided by technological innovation, constantly learning European technology and innovating equipment. It has independent intellectual property rights and provides customized solutions. Its products are known for their high efficiency, energy saving, environmental protection, and low prices. Kaibocheng adheres to strict quality control, and its machines have passed ISO9001 quality certification. Its service network covers the world and is committed to providing customers with reliable surface treatment equipment and comprehensive technical support, helping the industry upgrade to intelligence and green.

Jiangsu Kaibocheng Machinery Co., Ltd. takes “innovation driven, quality-oriented” as its mission, committed to researching and developing efficient and environmentally friendly surface treatment equipment, providing customized solutions for customers, and producing high-quality machines from the customer’s perspective. As a source manufacturer, Kaibocheng saves customers money, creates value for customers, and enhances the added value of bricks. Kaibocheng’s machines are pollution-free and promote green upgrading in the industry. We adhere to technological leadership and service supremacy, helping global customers improve production efficiency and create a sustainable industrial future for concrete bricks.

Jiangsu Kaibocheng Machinery Co., Ltd. has multiple invention patents and utility model patents. The company continues to innovate and its patented technology significantly improves equipment efficiency and environmental performance, providing customers with cost-effective solutions and consolidating its leading position in industry technology.

The Transformation From Ordinary Cement Bricks to Imitation Stone Bricks

Ordinary cement bricks undergo stone like transformation through processes such as shot blasting, soft brushing, and spraying: first, a shot blasting machine is used to create a stone texture base, then a soft brush is used to restore the color and luster of the natural stone, and finally, infrared spraying is used to enhance wear resistance and stain resistance. The finished product combines the texture of natural stone with the cost-effectiveness of cement bricks, with a 30% increase in compressive strength, and is widely used in high demand scenarios such as municipal and landscape.

How To Make Bush Hammer Texture Surface?

New Method to Make Bush Hammer Surface

The advantages of using shot blasting machine to process stone bush hammer surface are significant: through high-speed steel shot impact, a uniform and dense textured surface is quickly formed, with high simulation degree and no chemical pollution; Efficiency is 5-8 times higher than Bush hammer tool, with reduced costs, no need for water, cheaper consumables, precise control of roughness, enhanced anti slip and adhesion, while retaining stone strength, suitable for large-scale engineering applications, environmentally friendly and energy-saving.

Automatic Shot Blasting Machine For Bush Hammer Concrete Surface

Automatic shot blasting machine with palletizing machine greatly improves the efficiency of bush hammer concrete surface processing:

Automated assembly lines enable continuous loading, shot blasting, and discharge of stone materials, which is more than three times faster than traditional manual handling,24-hour continuous production, reducing labor costs by several times, with a daily output of over 1000 square meters, dust-free, efficient and environmentally friendly.

Related Machines

Jiangsu Kaibocheng Machinery manufacturing shot blasting machine,brushing machine for stone,curling machine,coating machine,dust collector,automatic package maching,automatic cuber stracker etc…

Why do concrete bricks paver slabs need shot blasting?

Addressing the pain points of traditional craftsmanship, replacing manual chiseling and bush hammer machines, the shot blasting machine achieves a uniform roughness of 0-5m brick surface in 1 minute, which is 20 times more efficient than manual labor and avoids high labor costs and inconsistent textures. It also replaces acid washing technology with no chemical pollution, meets environmental requirements, and eliminates the problem of waste liquid treatment.

What are the differences between bricks after shot blasting?

- Improved adhesion: When the surface roughness reaches Ra50-100 μ m, the bonding strength of cement mortar increases by 60%, increasing friction.

- Durability upgrade: After eliminating microcracks, the brick’s frost resistance compliance rate increased from 70% to 98%.

- Improve the grade of bricks to be comparable to natural stone.

Yes, KBC1050-3S shot blasting machine has 3 turbines,it can shot blast curbstone.

We can use automatic stacker or cuber stacker or by hand.

1-2 Workers.

1 Year.

35 days