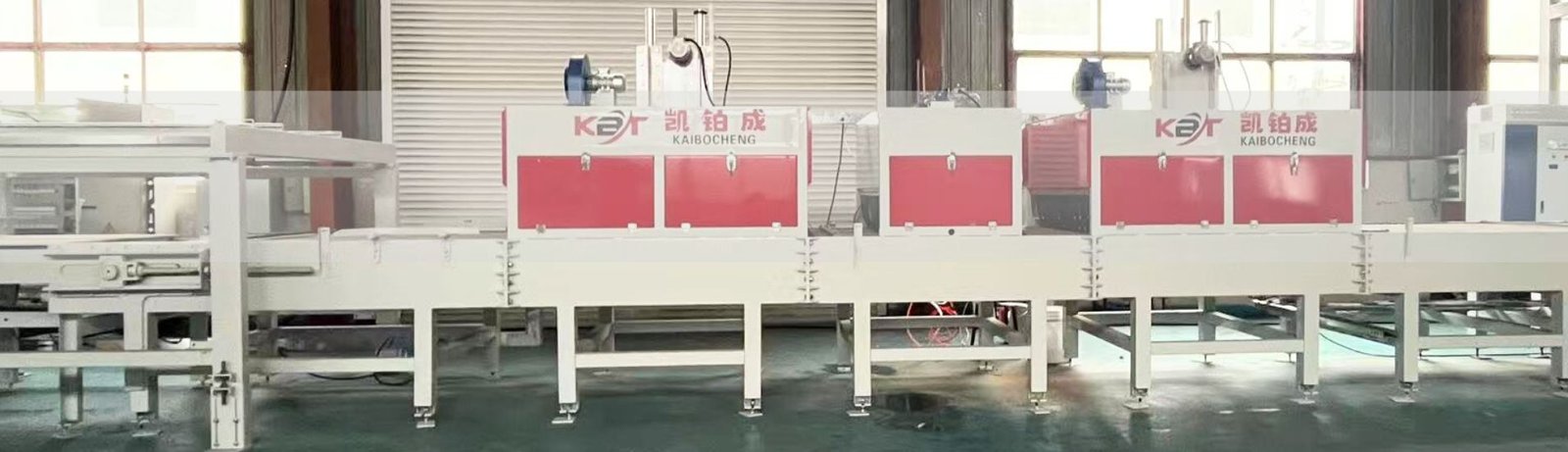

KBCPH-1050 Coating Machine For Concrete Products

| Size: | 5500*1500*1300mm |

|---|---|

| Power: | 59.31kw |

| Voltage: | 380V customized |

| Hertz: | 50Hz/60HZ |

| Capacity: | 0-5m/min |

| Working width: | 1000mm |

| Control system: | PLC control |

| Heating method: | Infrared heating |

Jiangsu Kaibocheng Machinery Co.,Ltd.-Focus On Concrete Products And Stone

Jiangsu Kaibocheng specializes in surface treatment of concrete products and stone, providing processes such as shot blasting machine, soft brushing antique style, curling machine,coating machine etc., committed to improving product texture and durability. We provides advanced technology, professional machines, and customized solutions to major brick block and stone factories, creating high-quality surface treatment solutions to help customers add value to their products.

KBCPH-1050 Coating Machine For Concrete Products By Type

3 Stations coating machine has 3 steps,preheating,coating and drying,the surface can only be coated with one layer, which is the basic version.

5 Stations coating machine has 5 steps,including preheating,coating,drying,coating,drying,its suitable for customers who require spraying two times or two types of protective coatings.

- Our Specialty

- Our Services

- Our Vision

Jiangsu Kaibocheng Machinery Co., Ltd. is a leader in the field of concrete and stone surface treatment equipment, with multiple core patented technologies covering processes such as shot blasting, antique design, soft brushing, and spraying. With innovative research and development and intelligent solutions, we provide customers with surface value adding refinement machines, serve global customers, promote industry technology upgrades with excellent quality, and establish a new benchmark for surface treatment.

The founder of Kaibocheng is a technical engineer, and the core team has been deeply involved in the industry for more than 20 years, driving development with technological innovation and establishing a leading position in the industry.

Kaibocheng is an enterprise that focuses on high-end customized solutions. Kaibocheng pays attention to details and quality, and with a senior team and rich industry experience, provides professional overseas debugging services, covering equipment installation, testing, and technical guidance, ensuring efficient and stable operation of global projects and becoming a trusted partner.

The vision of Jiangsu Kaibocheng Machinery Co., Ltd. is:

To become a leading global manufacturer of intelligent surface treatment equipment and technology, with the goal of innovation driven development and creating outstanding value for customers, promoting the progress of the global concrete brick industry, and achieving a sustainable future.

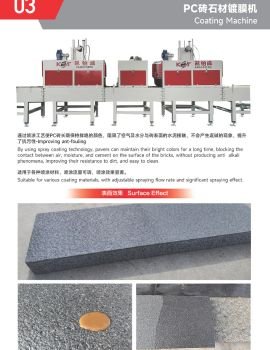

Automatic Coating Machine For Concrete Products

Kaibocheng coating machine adopts PLC intelligent control, automatically senses the material of bricks and stones, and accurately sprays. Fast heating, sensitive response, combined with palletizing machine to achieve automatic loading, full process automation operation, efficient and stable, greatly improving production efficiency, reducing labor costs, suitable for the needs of intelligent production lines.

Infrared Coating Machine Advantage

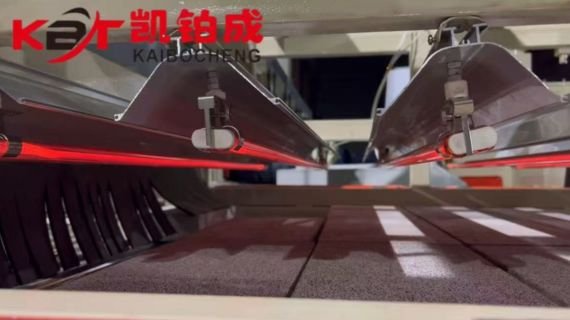

Infrared heating

has high efficiency and energy saving, directional heating, low heat loss, and low energy consumption.

Rapid heating, instant response, and improved production efficiency. Uniform heating to avoid local overheating and ensure stable coating quality. Accurate temperature control, intelligent adjustment, suitable for different material requirements. Safety and environmental protection: advantages such as no open flames, reduced pollution, and improved working environment.

Coating Machine Application

Kaibocheng coating machine is suitable for a variety of materials, including concrete bricks, paver blocks,curbstones, marble, granite, ceramic tiles, terrazzo tiles, quartz slabs, etc., and is widely used in the building materials, landscaping, and decoration industries. Its intelligent spraying technology adapts to different surface characteristics, ensuring uniform and firm coatings, improving product quality, meeting diverse production needs, efficient and material saving, and assisting in automation upgrades.

Related Machines

Jiangsu Kaibocheng Machinery has fully automatic shot blasting-curling-coating machine.

What are the benefits of infrared heating coating machines?

1. Improve the curing efficiency of coatings

Quick drying: Infrared radiation directly radiates heat energy, accelerating the curing of coatings or coatings (such as paint, epoxy resin, waterproof materials) and reducing waiting time.

Uniform heating: With strong infrared penetration, the coating can be heated synchronously inside and outside, avoiding surface cracking and internal dryness issues.

2. Energy conservation and environmental protection

Precise heating: Only directional heating is applied to the spraying area, reducing energy waste (saving about 30% -50% energy compared to traditional hot air drying).

No exhaust emissions: No need to burn fuel, reducing CO ₂ emissions, in line with environmental requirements.

3. Improve coating quality

Reduce bubbles and cracks: Uniform heating can reduce defects in coatings caused by temperature stress.

Enhance adhesion: Infrared heating can activate surface molecules of the substrate, improving the bonding strength between the coating and the brick.

Retain coating performance: avoid decomposition of coating components caused by high temperature hot air (such as certain polymer coatings).

4. Adapt to complex scenarios

Suitable for low temperature environments: It can still work effectively in winter or humid environments and is not affected by external temperature.

Yes,it is.

Yes,we have it.

Yes,we do.

1 Year.

30 days.