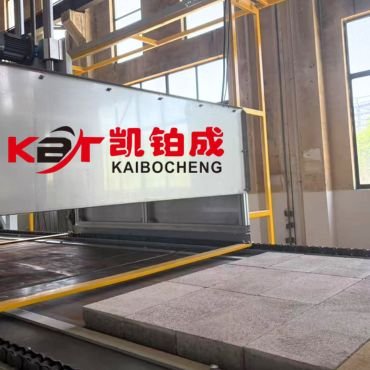

KBCPH-1300 Coating Machine

| Size: | 5500*1500*1300mm |

|---|---|

| Power: | 59.31kw |

| Voltage: | 380V customized |

| Hertz: | 50Hz/60HZ |

| Capacity: | 0-5m/min |

| Working width: | 1000mm |

| Heating method: | Infrared heating |

| Control system | PLC control |

KBCPH-1300 Coating Machine For Concrete Products

The concrete brick blocks spraying coating machine is a specialized equipment for automated coating of brick surfaces. It uses infrared heating and low-voltage PLC control pulse coating to evenly spray waterproofing agents, coloring agents, or protective coatings. It has the characteristics of high efficiency, low consumption, and intelligent control, significantly improving the weather resistance and decorative properties of bricks. It is suitable for batch processing of permeable bricks, paving slabs, interlocks, paver blocks, etc., improving the performance and service life of bricks.

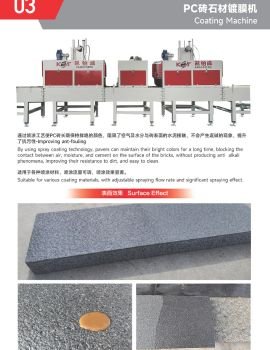

KBCPH-1300 Coating Machine For Concrete Products and Stone

The 3station coating machine includes preheating,coating, and drying, and is suitable for small and medium-sized brick block manufacturers.

The five station coating machine includes preheating, coating, drying, coating, drying, and can coat twice, suitable for companies with high requirements for spraying technology.

- Our Technology

- Our Mission

- Our Patents

The coating technology developed and produced by Jiangsu Kaibocheng Machinery Co., Ltd. adopts an intelligent pulse spraying system to accurately control the atomization particles of the coating, achieving efficient film coating on the surface of concrete bricks, stone and other materials. The equipment is equipped with PLC automatic adjustment of spraying parameters, with a coating utilization rate of over 95%, which is 40% more energy-efficient than traditional processes. It supports multifunctional coatings such as waterproof, stone like, and anti slip, with a large daily processing capacity, helping to upgrade the surface treatment of building materials.

Jiangsu Kaibocheng Machinery Co., Ltd. is committed to the mission of “intelligent manufacturing and precision equipment, empowering green building materials”, with the core of ensuring that every building material can withstand the test of time, and focusing on the research and development of efficient and energy-saving surface treatment technologies. We help customers improve product quality and production efficiency by innovating intelligent equipment such as shot blasting and spraying, and promote the transformation of the construction industry towards environmental protection and intelligence. Adhere to the concept of technological leadership and service supremacy, provide cost-effective solutions for global users, and create a sustainable industrial future together.

Jiangsu Kaibocheng Machinery Co., Ltd. has more than 20 national patents, covering fields such as intelligent shot blasting, efficient dust removal, and automated spraying. Its core technologies include “multi head linkage control system” and “pulse back blowing dust removal process”. Promote technological upgrading in the surface treatment industry with innovative strength.

KBCPH-1300 Coating Machine For Concrete Products With PLC Control

PLC intelligent control, adjustable parameters, automatic sensing brick, using infrared light, fast heating, low thermal inertia, high temperature resistance, corrosion resistance, stable thermal chemical performance, long service life, high insulation strength.

KBCPH-1300 Coating Machine With Multi-functions

Kaibocheng’s coating machine

can spray concrete bricks, paver blocks,curbstones, and paving slabs, step blocks,antique bricks, stone, marble, granite, terrazzo, etc., sprayed with specific chemical materials, have a long-lasting color, are resistant to weathering and pollution, anti-dirty,have a long lifespan, and can also solve the problem of alkali resistance in concrete products.

KBCPH-1300 Coating Machine With Infrared Heating

Kaibocheng spray coating machine adopts advanced infrared preheating and drying technology, which heats up quickly, accelerates the adhesion of chemical spray coating solvents through preheating, and shortens the drying time through drying. Infrared heating is uniform and efficient, energy-saving and environmentally friendly, suitable for various building materials such as stone and concrete products, ensuring smooth and durable paint surfaces, significantly improving production efficiency and product quality.

Related Machines

Jiangsu Kaibocheng Machinery co.,ltd. produces shot blasting machine for concrete pavers,dry brush machine,curling machine,coating machine,dust collector,automatic package system,automatic cubing system…

Why do bricks pavers need to be coated?

1.Waterproof and moisture-proof: Coatings can form a protective layer, reduce the water absorption rate of bricks, prevent freeze-thaw damage or mold growth caused by moisture.

2.Weather resistance: Resist natural erosion such as ultraviolet rays, acid rain, and weathering, and extend the service life of bricks.

3.Anti pollution and easy to clean: Some coatings have hydrophobicity, making it easy to clean surface stains

4.Prevent alkali reflux.

What spraying material should be selected?

Various spray coating chemcial materials are available on the market

- Water based

- Oily based

- Stone specific spraying materials

Yes,wee supply.

Yes,it can.

Yes,we have it.

1 Year.

30 days