Steel Shots:

Steel shots are sidely used in multiple industrial fields:

- Surface treatment and cleaning

- Foundry industry

- Auto manufacturing

- Ship engineering

- Composite materials

- Mechanical processing and manufacturing industry

- Stone and concrete products, building materials

- Tire manufacturing

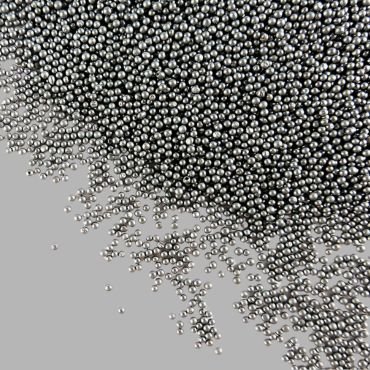

What is Steel Shots?

Steel shots is a commonly used metal abrasive, and common steel balls include alloy, stainless steel, cast iron, carbon steel shots etc. Due to its high hardness, good wear resistance, and recyclability, steel shots are widely used in multiple industrial fields.

Steel shot has become an indispensable consumable in modern industry due to its high efficiency and environmental friendliness (recyclability), especially in the field of surface treatment.

By high-speed spraying of steel shot to strengthen the metal surface, the fatigue strength and stress corrosion resistance of the workpiece are improved. Before painting, electroplating or spraying, the surface is cleaned with steel shot to enhance the adhesion of the coating. It can also be used to remove impurities such as oxide scale, rust, welding slag, etc. on the surface of castings, forgings and welded parts

Steel Shots By Type

There are alloy, stainless steel, cast steel, carbon steel shots

Alloy steel shot is used for surface cleaning, strengthening, rust removal, casting sand removal, automotive parts treatment, ship paint removal, mold polishing, stone shot blasting, etc.

Stainless steel shot is used for anti-corrosion and rust prevention surface treatment of food machinery, chemical equipment, medical devices, precision parts, ship components, etc.

Steel shot is used in industrial fields such as casting sand removal, surface rust removal, steel plate descaling, metal strengthening, shot blasting cleaning, pre-treatment coating, etc.

Carbon steel shot is used in industrial fields such as metal rust removal, surface cleaning, shot peening, casting sand removal, steel plate descaling, and coating pretreatment.

Steel Shots By Size

There are different particle sizes steel shots available

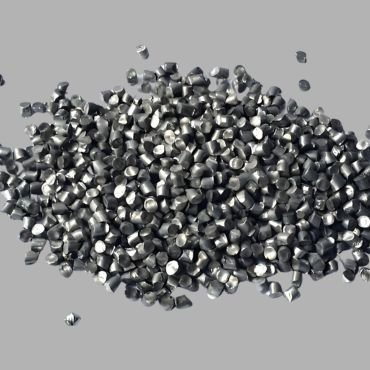

Steel Shots By Shape

Steel shots has round and irregular shape.

Steel Shots Feature Box

ISO9001

High Quality

Good Service

Good Price

High Hardness And Wear Resistance Steel Shots

The steel shot made of Kaibocheng has extremely strong wear resistance and fracture resistance, can withstand repeated high-speed impacts, and is suitable for harsh metal strengthening and heavy-duty cleaning scenarios. Its high carbon or alloy material ensures shape stability even after long-term use, significantly extending service life and reducing replacement frequency. It is particularly suitable for efficient operations such as stone surface treatment, automotive parts shot peening, casting sand removal, and thick oxide layer treatment.

Uniform Particle Size and Regular Shape Steel Shots

Steel shot with uniform particle size and regular shape can ensure consistent distribution of impact force and improve the stability of treatment effect. Circular steel balls have good fluidity and are suitable for precision strengthening and polishing; Irregular steel grit has strong cutting force and specializes in efficient cleaning.

Accurate grading (such as 110-S930) can match different process requirements, avoid excessive damage to the substrate, and optimize equipment wear and energy efficiency, which is a key guarantee for surface treatment quality.

Recyclable Steel Shots

Recyclable steel shots can be reused after sorting and dust removal, significantly reducing consumable costs. Its high durability (HRC 40-65) ensures stable performance even after multiple impacts, reducing waste pollution. Equipped with an automated recycling system, the utilization rate is increased by over 30%, balancing efficient production and environmental protection requirements. It is widely used in large-scale surface treatment fields such as casting and shipbuilding.

Jiangsu Kaibocheng Machinery Co.,ltd.

Jiangsu Kaibocheng Co., Ltd. has obtained ISO9001 certification and specializes in producing concrete shot blasting machines and stone shot blasting machines, curling machine, Spray painting machines, steel shot machines, palletizing machines and other equipment, with cutting-edge technology and strict quality control as their core advantages. Serving global customers, providing customized solutions and efficient after-sales service, committed to becoming a quality benchmark and innovation leader in the field of surface treatment.

Steel Shots Package and Delivery

Steel shot packaging usually uses double-layer woven bags or ton bags (1000kg) with a weight of 25kg, lined with moisture-proof film to ensure dust and oxidation prevention during transportation. Export standard packaging can be reinforced with customized pallets, with labels indicating specifications, materials, and production batch numbers for easy warehouse management.

Steel balls are shipped in standard containers (20GP/40HQ) with ton bags or pallets fixed inside. Moisture proof and rust proof packaging, strict checking of specification labels before packing to ensure transportation safety, supporting global sea and land transportation, efficient and convenient.

Steel Shots Applications

Special steel shot for stone shot blasting machines needs to have high hardness and wear resistance, with a particle size of S330-S550 (0.8-1.4mm). It is used for efficient roughening, cleaning, or antique treatment of concrete bricks, marble, and granite surfaces, ensuring uniform texture without damaging the substrate, and can be recycled to reduce costs.

Steel shot is used in the casting industry, accounting for about 40%. Its core purpose is to clean sand, remove oxide scale and surface burrs from castings. For example, cleaning of automobile engine cylinder blocks, valves, and pipeline castings.

Steel shot is used in the automotive manufacturing industry, accounting for about 30%. Its core applications include shot peening of components such as springs, gears, and crankshafts to enhance their fatigue resistance.

- Gallery

- Data Sheet

- Details

| Customized support | OEM |

| Brand name | Kaibocheng |

| Model number | S70-S930 |

| Usage | For blasting , shot peening , surface treatment |

| abrasive grain sizes | 0.2mm-2.5mm |

| Material | Alloy Steel |

| Certificate | ISO9001 |

| Density | 7.4g/cm3 min |

| Shape | Round |

| Hardness: | 40-50HRC |

The high-quality steel balls from Jiangsu Kaibocheng Machinery Co., Ltd. have passed ISO9001 certification and have high hardness and strong wear resistance. They are widely used in industries such as casting sand cleaning, automotive strengthening, ship rust removal, steel plate descaling, and stone treatment. They are durable and significantly improve surface treatment efficiency and quality.

Related Product

Why choose Steel Shots From Jiangsu Kaibocheng Machinery Co.,Ltd.?

1. ISO9001 certified quality

2. Super durable and wear-resistant

3. Industry wide adaptability

4. Low price

25kg/Bag,1Ton/outter Package

3-30days.

1 Ton

Yes,we can.

Yes,we have.