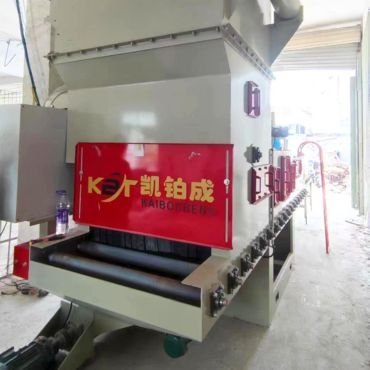

Stone Shot Blasting Machine Model: KBC1300

Stone shot blasting machine can handle various materials of stone, such as marble, granite, limestone, etc.

- Reducing producing cost

- Energy conservation and environmental protection

- Enhance the aesthetics of stone

- High efficiency

- No water

- No dust

- Oversea service

What is Stone Shot Blasting Machine

The stone shot blasting machine is mainly used for marble, granite, and quartz. Through steel shot ejection, it impacts the surface of the stone,to remove stains, oxide layers, wear and defects on the surface of stone in this way, turning it into a rough texture with a lychee surface and a three-dimensional effect, increasing its aesthetic appeal. Commonly used on sidewalks or squares, it has an anti slip effect.

Stone shot blasting machine is mainly consists of shot blasting room, roller conveyor, turbine, shot circulation system (including elevator, separator, longitudinal spiral conveyor and shot supply pipeline), dust removal, purgingsystem, electrical control and other components.

Stone shot blasting machine is a continuous shot blasting operation with continuous feeding, processing large batches with high work efficiency.

It can also be suitable for different surface treatment requirements, such as shot blasting and removing oxide layers. The operation of stone blasting machine is very simple. Simply place the stone inside the machine and press the switch to complete the surface treatment work.

Stone Shot Blasting Machine By Model

Kaibocheng machinery manufacturing concrete paver block shot blasting machine and stone shot blasting machine,this two type shot blasting machines are different.

Stone shot blasting machine has different model,distinguish by machine’s width.

KBC900 Stone shot blasting machine can process stone with max width 800mm,usually stone ‘s width is 600mm,or 800mm,so this model is espscially for common stone surface shot blasting.

KBC1800 Stone shot blasting machine is customized for customer,this customer’s stone slab width is 1600mm 1700mm,if you have your stone special width, we can OEM shot blasting machine for you.

Stone Shot Blasting Machine By Turbine

Stone shot blasting machine has 2 turbines,and 4 turbines,it depends on machine’s model and customer requirements.

Stone Shot Blasting Machine By Function

Product Feature Box

Production without water

Reduced Cost

High-power motor

Advanced structure

Powerful Turbine for Stone Shot Blasting Machine

Kaibocheng Machinery produces its own turbines, with each component such as vanes, impellers, separator, directional cages, top plates, end plates, side plates, etc. It has good wear resistance and is equipped with a branded motor. The quality of each step is controllable.

The variable frequency high-power turbine has good sealing performance, large flow rate, good steel shot circulation, and excellent performance.

Unique Structure Stone Shot Blasting Machine

The high-performance stone shot blasting machine produced by Kaibocheng Machinery has multiple patents, and its unique design ensures good sealing of the entire shot blasting. It has an excellent steel shot separation and circulation system, effectively improving production efficiency.

Stone Shot Blasting Machine without Dust

During the operation of the shot blasting machine, a large amount of dust is generated, which can pollute the environment and have adverse working effects. The Kaibocheng pulse dustt collect bag and structure filter purifies the dust emitted by the shot blasting machine through the filtering effect of the bag and the gas cleaning effect. The entire process is free of dust, effectively improving the quality of the working environment and complying with environmental policies.

Kaibocheng is Professional Stone Shot Blasting Machine Manufacturer in China

The traditional processing method for lychee surface stone is grinding with a grinding wheel or manual polishing, which requires water and is inefficient, costly, and slow in efficiency. The Kaibocheng stone shot blasting machine has overturned traditional processing methods, eliminating the need for water in lychee noodle processing, reducing processing costs, and improving economic efficiency.

Inpsection and Delivery

Although we strictly control every production process, we still inspect every shot blasting machine. Only when there are no problems during the inspection can it be considered qualified and shipped to every customer. We have a dedicated quality inspection department, and qualified machines are the basic guarantee of our quality.

From the picture, it can be seen that our machines are carefully packaged before shipment, fearing that they may be damaged during prolonged transportation. We hope to protect the equipment as much as possible, even the paint needs to be well protected, so that customers can rest assured. This is our wish.

Stone Shot Blasting Machine Lastest Projects

Kaibocheng Machinery has specially developed a stone shot blasting machine, and its motor size is different from that of a concrete products shot blasting machine, and the design of the shot blasting machine is also different. The picture shows a photo of Kaibocheng’s shot blasting machine installed in a granite factory.

From the picture, it can be seen that the shot blasting machine is blasting granite, and the surface effect is very obvious. The efficiency of using the shot blasting machine to process granite lychee surface is very high, reducing labor and saving abrasive costs. The steel balls of the shot blasting machine are durable, which improves customer profits.

- Gallery

- Data Sheet

- Details

| Technical parameter | |

| Model | 1050 |

| Working width | 900mm |

| Product thickness | Adjustable |

| Production speed | 0-5M |

| Power | 18.5kw |

The stone shot blasting machine mainly consists of shot blasting chamber room, conveyor, turbine, shot circulation system (including elevator, separator, longitudinal spiral conveyor and steel shot supply pipeline), dust removal, cleaning system, electrical control and other components.

The high-speed rotating steel balls are impacted and rubbed against the surface of the stone by centrifugal force, making the surface of the stone uneven, like the surface of a lychee, with a natural beauty.

Meanwhile, the stone shot blasting machine can also achieve different shot blasting effects by adjusting the particle size of the steel shot.

The stone shot blasting machine has the following advantages:

1. Efficiency: The stone blasting machine can complete a large amount of surface treatment work for stones in a short time, greatly saving a lot of manpower and time costs.

2. Energy saving and environmental protection: The stone shot blasting machine uses high-speed rotating steel balls for surface treatment, without the need for any chemicals or cleaning agents, avoiding environmental pollution and reducing energy consumption.

Related Product

Why use a stone shot blasting machine to process stone?

(1) Low production cost.

(2) The surface roughness of stone can be determined by selecting different types of steel pellets according to different needs.

(3) Steel shot blasting has the advantage of high efficiency.

(4) The production process is environmentally friendly and energy-saving, does not require water, does not produce wastewater, and does not damage the environment. The latest shot blasting technology using steel shot has replaced the previous quartz sandblasting, and the dust level has been reduced to the lowest level. Steel shot can be recycled and reused.

(5) The shot blasting process for surface treatment of stone mainly produces steel balls made of alloys, so it will not cause rust spots on the surface of stone caused by ordinary steel balls.

(6) The processing quality of products treated with steel shot is stable because using the same standard steel shot will automatically control during the shot blasting process, and the surface texture of the workpiece will be cleaned evenly.

In addition to stone shot blasting technology, there are also processing methods such as fire method and lychee noodle machines for stone processing.

Fire method is a way of heating stone by burning, which causes the internal crystals of the stone to burst and form destructive patterns, reducing the service life of the stone.

The stone lychee surface machine also uses machine processing methods to polish the surface of the stone by rotating the blade. Although the processing speed is improved compared to the fire burning technique, the cost is very high and the speed is very low.

So the advantages of stone shot blasting machine compared to the above two processing technologies are reflected. It can ensure processing speed, save processing costs, and is more environmentally friendly compared to the other two traditional processing technologies. It is currently the best way to roughen stone.

30-60 days

Yes we have.

Yes,we supply stone shot blasting machine spare parts.

Yes,welcome visit us,and we also have stone shot blasting machine’s working video.